In the April, 2018 issue of Between The Branches, Tigercat explains how they’ve implemented robotic welding to keep up with demand of their Tigercat machines. Robotic welding systems from Wolf Robotics has helped Tigercat match production output to the growing market demand while increasing quality and efficiency. Read the complete article here.

Read MoreWhat's Happening at Wolf Robotics

RPG Off-Road was created with one simple goal in mind, and that is to advance the Raptor® and F-150 platform to new heights. RPG has teamed up with the best of the best in the Off-Road industry to bring Ford F-150 & Raptor owners after-market performance upgrades, such as suspension and bumpers. When you are…

Read MoreFIRST, CONSIDER IF AUTOMATION IS REALLY RIGHT FOR YOUR NEEDS. The trend toward automation is accelerating rapidly as businesses all over the world realize it’s a necessity in order to remain competitive, but is robotic automation right for your processes? Before you jump into automation, it’s important to consider whether or not your process and…

Read MoreIn 2007, Scott started at Wolf Robotics as an intern…while attaining his mechanical engineering degree from Colorado State University (CSU). His first role at Wolf Robotics was working on the floor in the Assembly Department. During his time in Assembly, Scott learned how to build a robotic welding system from the bottom up. He moved…

Read MoreWe often hear from businesses who are contemplating adding automation to their fabrication process. To help with your decision making, we’ve put together this handy document that outlines the top 5 reasons to consider automation. Download 5 Reasons to consider automation document. Introducing Fab-Pak We’ve recently launched our Fab-Pak™ standard welding systems. Fab-Pak systems are…

Read MoreWe’ve had a great couple days here at FabTech. Be sure to stop by and see us at the Lincoln Electric booth. You can talk to our 3D Metal Printing expert, view a standard Ferris Wheel system and explore our automation systems in virtual reality. We hope to see you soon. …

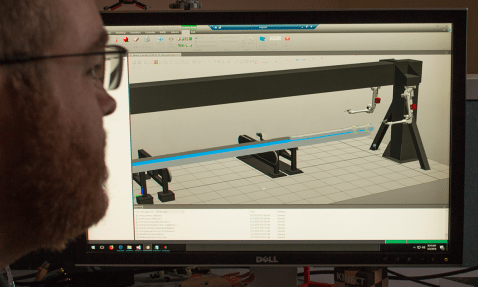

Read MoreThe Challenge Our customer, a leader in heavy equipment, contacted us to build a custom robotic system to weld sub-assemblies. The system was required to be flexible and accommodate over 400 versions of the customer’s part models, ranging from 6-10 ft. in length. The main goal of this project was to develop a tooling system…

Read MoreBoulder, Colorado, October 24, 2017 The Colorado Photonics Industry Association (CPIA) will name Wolf Robotics, a subsidiary of Lincoln Electric, as the 2017 Colorado Photonics Company of the Year. The award will be presented to Wolf Robotics of Ft. Collins, Colorado, on Tuesday, October 24th 2017 at the CPIA Annual Meeting held at the University…

Read MoreFlowmaster®, a customer of Wolf® Robotics since 1996, is the leading manufacturer of high performance stainless steel exhaust systems, street performance and race mufflers, cold air intakes, tuners, exhaust accessories, and more for most popular modern cars, classic cars, trucks, and SUV’s. Through the years, Wolf Robotics has manufactured several robotic welding systems for Flowmaster….

Read MoreROS Industrial recently shared an article on their website about the robotic blending project. Starting in earnest at the beginning of 2017, Milestone 4 (M4) sought to further the functionality of the technology to incorporate functionality that was of interest to the participating members. These members, 3M, Caterpillar, GKN Aerospace, Wolf Robotics, and the SwRI development…

Read More