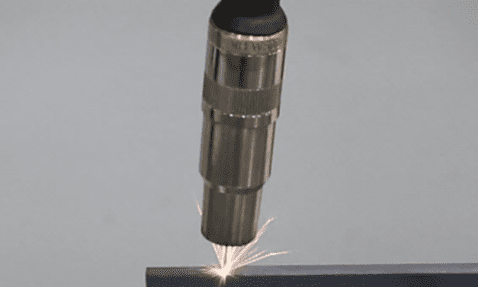

Perfect part fit-up doesn’t always happen and some weld seams are simply not repeatable. That’s ok…we have a solution. For the robot to weld these seams, which are out of tolerance, Wolf Robotics equips the robotic welding with Wolf TouchSense, a tactile sensing capability. Wolf TouchSense works by applying a safe voltage either to the…

Read MoreRecent News News

If you’re working with the right robotic integrator the relationship between you and your integrator should be a partnership where the integrator works with you closely from start to finish to deliver the right solution. Your integrator should be a trusted adviser, someone you can rely upon and someone you know will get the job…

Read MoreAt Wolf Robotics, we often hear from many of our customers regarding their pain points such as: how they constantly have to adjust due to the lack of skilled welders the need to improve weld quality and consistency having to reduce costs to remain competitive the need to speed up production These industry realities are…

Read MoreWhen will additive manufacturing make sense for the job shop? Emerging technologies are printing large metal parts now Additive manufacturing (AM) is still young. Proponents continue to improve the processes, expand workable materials, and develop new deposition techniques. All have, or will have, the ability to enhance and complement traditional manufacturing processes well beyond the…

Read MoreIn the April, 2018 issue of Between The Branches, Tigercat explains how they’ve implemented robotic welding to keep up with demand of their Tigercat machines. Robotic welding systems from Wolf Robotics has helped Tigercat match production output to the growing market demand while increasing quality and efficiency. Read the complete article here.

Read MoreRPG Off-Road was created with one simple goal in mind, and that is to advance the Raptor® and F-150 platform to new heights. RPG has teamed up with the best of the best in the Off-Road industry to bring Ford F-150 & Raptor owners after-market performance upgrades, such as suspension and bumpers. When you are…

Read MoreFIRST, CONSIDER IF AUTOMATION IS REALLY RIGHT FOR YOUR NEEDS. The trend toward automation is accelerating rapidly as businesses all over the world realize it’s a necessity in order to remain competitive, but is robotic automation right for your processes? Before you jump into automation, it’s important to consider whether or not your process and…

Read MoreThe Challenge Our customer, a leader in heavy equipment, contacted us to build a custom robotic system to weld sub-assemblies. The system was required to be flexible and accommodate over 400 versions of the customer’s part models, ranging from 6-10 ft. in length. The main goal of this project was to develop a tooling system…

Read MoreFlowmaster®, a customer of Wolf® Robotics since 1996, is the leading manufacturer of high performance stainless steel exhaust systems, street performance and race mufflers, cold air intakes, tuners, exhaust accessories, and more for most popular modern cars, classic cars, trucks, and SUV’s. Through the years, Wolf Robotics has manufactured several robotic welding systems for Flowmaster….

Read MoreWe just got these VERY LARGE tools in this morning. Each tool has over 500 parts and were designed by our engineer Lee Stutzman. Many of our customers need custom industrial tooling and we’re more than happy to help. Give us a call!

Read More